Tool Management Services from Process Engineering to Supply Chain Management Can Streamline Shop Operations

Dr. Götz Marczinski

Value-added Services offered by tool manufacturers and commodity suppliers have changed greatly in recent years. Tool-vending machines, now a Standard feature of each Service contract, are obvious evidence of that development. But, as CIM Aachen GmbH, the provider of tool management Solutions and Services, points out, they represent just the tip of an iceberg.

Case Study

Take the real-world case of a medium-sized manufacturer and supplier of drop-forged components who has 340 employees and revenues of roughly 50 million a year.

Its main products are safety-related automotive components.

As the Company was competing for a follow-up contract to supply flanges for the brake assembly in light trucks, it had to identify areas for significant cost savings relative to the predecessor part. Most of the necessary cost reductions would have to involve the machining process, including the cutting tools. Thus, the Company invited three qualified tool suppliers to offer their best solution for both the machining process and tool supply logistics.

The most promising approach turned out to be an integrated Service bundle of engineering support and tool supply logistics. The winning supplier found a way to machine the two versions of the flanges in just two Setups using a maximum of 16 tools for 35 operations.

To secure the tool supply in a highly flexible manufacturing environment, the supplier implemented an effective approach for tool changes. All tools are equipped with a data chip that helps automate the changes. At a predefined stage of life, each tool is automatically replaced to keep part quality within specs. The chip even allows for the tool magazines to be stocked randomly.

The supplier is also in Charge of tool logistics, from tool supply to cutter grind. Besides each machining centre having its basic set of tools, a certain number of both Standard and Special tools are stocked in tool-vending machines. That makes out-of-stock situations a thing of the past and frees the toolroom from simple handling and booking tasks.

Lessons Learned

The principal conclusion to be drawn from this case, argues CIM, is that the Company that knows what it needs will get first-rate

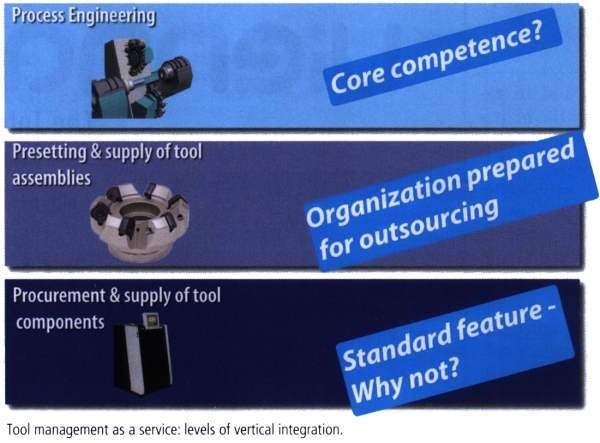

Service from qualified suppliers. Asking a few questions will help a Company determine what level of vertical integration serves it best.

Companies emulating the one in the case study may see the highest productivity gains, but they become more aepenaent on their supplier. Considering such support in process engineering means introducing questions about future core competencies. Also, not every Company can realistically let a supplier run the shop-floor tool Operation. Small and medium-sized enterprises in particular often lack the clear organizational structure that would be a prerequisite for accommodating an outsourcing project.

But supplying tool components via supplier-operated tool-vending machines is the State of the art. The question for every manufacturing Company, ready to switch or not, should be not whether to pursue this course, but rather how to do it.

erschienen in European TOOL & MOULD MAKING, 09/2008